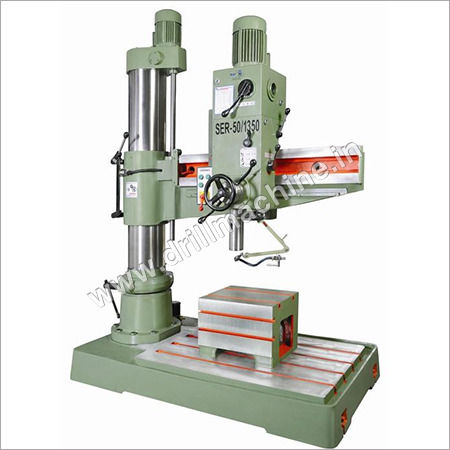

Geared Radial Drilling Machine

Price 250000.0 INR/ Unit

Geared Radial Drilling Machine Specification

- Dimension (L*W*H)

- 1750X1000X2000 Millimeter (mm)

- Condition

- New

- Spindle Speed

- 90 to 1000 RPM

- Product Type

- Radial Drilling Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- Normal

- Voltage

- 220 - 380 Volt (v)

- Power Source

- Electric

- Weight (kg)

- 1200 Kilograms (kg)

- Capacity

- 40 mm

- Color

- Green

Geared Radial Drilling Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- PIPVAV, MUNDRA

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Gunny Bag

- Main Export Market(s)

- North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, Australia

- Main Domestic Market

- All India

- Certifications

- ISO

About Geared Radial Drilling Machine

SYNDICATE INDUSTRIAL CORPORATIONaims at creation of wide industry platform in the field of manufacture of All Geared Radial Drilling Machine in wide ranges with mutual benefit between suppliers and buyers besides maintaining services help and closed links

Some important features

Heavy Duty Cast Iron with maximum working space provided with standard TSlots leveling and foundation bolt holes and builtin coolant tank

Forged alloy steel spindle finished grounded to close tolerances and mounted on heavy duty anti friction bearing to withstand heavy radial as well as thrust loads

Heavy Duty Precision machined from forged with grinding EN8 gear material and suitably heat treated for maximum wear resistance

Conveniently grouped for ease of operation and maximum efficiency

Machines are finished with long lasting wear resistant paint All bright components are suitably treated for protection against oxidization

ElectricalBuilt in quality electrical are easily accessible for operation and maintenance

Description

Capacity and Size

Drilling Capacity In MS

40mm

Drilling Capacity In CI

45mm

Tapping In MS

25mm

Rough Boring In MS

60mm

Spindle Nose Tapper

MT4

Spindle Travel

175mm

Number Of Spindle Speed

8

Range Of Spindle Speed

90 TO 1000 RPM

Number Of Power Feed

2

Range Of Power Feed

020010mm

Drilling Radius MaxMin

1115550mm

Distance From Column To Spindle Max Min

1020400mm

Distance from Spindle to Base MaxMin

1180430mm

Diameter Of Coulmn

210mm

Vertical Power Movement Of Arm

750mm

Horizontal Movement Of Drilling Head

630mm

Box Table LXWXH

510 X 380 X 355

Base Plate Area

1625 X 850 X 190

Working Surface

1020 X 650

Number Size Of TSlot

316mm

Drilling Motor TWO SPEED

15 KW 50 Cycle 1440 RPM 15 KW 50 Cycle 2800 RPM

Elevation Motor For ARM

075 KW 50 Cycle 1440 RPM

Shipping Size Approx L X W X H

1750 X 1000 X 2000

Standard Equipment

Electrical Complete Drill Drift Leveling Bolt and Pad Oil Can and Manual Book

Optional equipment

Box table Slotted Coolant Pump with FittingDrill Chuck and Arbor Drill Vice Drill Sleeve

Precision and Power for Industrial Drilling

The Geared Radial Drilling Machine delivers reliable performance for heavyduty drilling Its geared drive system ensures consistent torque while the 40 mm capacity suits a wide range of mild steel workpieces The semiautomatic mechanism increases throughput while minimizing manual intervention ideal for demanding production environments

UserFriendly Operation and Versatility

Designed for effortless use this semiautomatic drilling machine features a straightforward interface adjustable spindle speed from 90 to 1000 RPM and robust mild steel construction Suitable for varied workshop needs its flexibility makes it a staple for manufacturers service providers and fabricators alike

FAQs of Geared Radial Drilling Machine

Q How does the semiautomatic feature benefit operators of this radial drilling machine

A The semiautomatic operation reduces manual involvement enhancing efficiency and consistency during repetitive drilling tasks Operators can focus on overseeing the process instead of handling every step minimizing fatigue and optimizing productivity

Q What types of materials can be drilled using this machine

A This radial drilling machine is designed primarily for mild steel but it can accommodate similar metals within its 40 mm drilling capacity provided the workpiece and tool selection align with the machines capabilities

Q When is it advisable to use a geared radial drilling machine over other drilling types

A A geared radial drilling machine should be used when precise heavyduty drilling on substantial or cumbersome workpieces is required Its movable arm and adjustable spindle offer superior flexibility for large or awkward parts compared to standard pillar drills

Q Where can I install and operate this drilling machine

A Its robust design and size 1750x1000x2000 mm make it suitable for installation in spacious industrial workshops production lines and fabrication units Ensure the site has a compatible 220380 V electric supply and adequate flooring to support 1200 kg

Q What is the process for adjusting spindle speed on this machine

A Spindle speed can be tailored between 90 and 1000 RPM through the machines geared mechanism allowing users to match the RPM to specific materials and drill sizes for optimum cutting performance and tool longevity

Q How does the 40 mm drilling capacity enhance production capabilities

A A 40 mm drilling capacity allows operators to tackle larger diameter holes in thick mild steel components expanding the scope of projects that can be managed inhouse and reducing the need for multiple drilling setups or outsourcing

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Geared Radial Drilling Machine Category

All Geared Radial Drill Machine

Price 800000.0 INR / Number

Minimum Order Quantity : 1 Number

Table Size : 600X500X500

Spindle Speed : 30 TO 1300 RPM

Power Source : Electric

CNC Or Not : Normal

Automatic Geared Radial Drill Machine

Price 290000 INR / Number

Minimum Order Quantity : 1 Number

Table Size : 380X300X300

Spindle Speed : 60 TO 1000 RPM

Power Source : ELECTRIC

CNC Or Not : Normal

Heavy Duty All Geared Radial Drilling

Minimum Order Quantity : 1 Piece

Table Size : 580x380x300

Spindle Speed : 60 TO 1800 RPM

Power Source : Electric

CNC Or Not : Normal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry